Pad printing accessories overview

| Pretreatment units | |

| Depending on the type of material which is to be printed, the surface must be pre-treated so that it can take on the colour. For good results the print material must have a surface tension of at least 38 mN/m; otherwise the ink might smudge. We offer system-integrated pre-treatment units, as well as customer-specific individual solutions. In addition to treating with corona, flames or plasma for increased surface tension, we also offer ionisation units which reduce electrostatic charging. |

| Pretreatment overview | |

| Drying | |

| The process of drying requires air, warm air, infrared or near-infrared light.UV light is needed for UV inks. We offer drying devices integrated into our machines as well as individual solutions tailored to your needs. |

| Drying overview | |

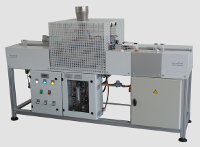

| Ecocleaner | |

| The ecoCleaner is a eco-friendly developed cleaning unit for pad printers. Compared to conventional solvent cleaning units which work with thinner, the ecoCleaner employs a special cleaning medium that is water-based. This cleaning Agent is virtually odorfree and of course non-explosive and non-flammable. The soiled cleaning Agent is recycled within the unit and can therefore be re-used continuously. Merely the loss due to dispersion must be replaced from time to time. The separated soiled ink is automatically removed from the unit and deposited into a waste container (front of machine). The ecoCleaner can be placed directly in any working environment. It is perfectly safe and there are no environmental hazards. |

| Ecocleaner overview | |

Catalog

Catalog  Book

Book