All parameters, including the correction of the print positioning, can be accessed via the touch screen. Several machines can be controlled with one touch screen. This allows the tool free setup of one machine or even an entire facility with several modules through a single touch screen. All parameters can be saved and re-accessed.

- Closed inkwell system

- Pad cleaning

- XYZ positioning over touchscreen

- Print sequence freely definable

- Automatic ink thinners

- pad shuttle

- Electric one- or two-axes rotary devices.

- Digital interfaces or real-time Ethernet

- Automatic parameter backup on a company server

| wo.c. 1800/hr, w.c. 1200/hr |

| max. 290N |

| pneumatic & linear motor |

| 44 l/min |

| 5–6 bar (87 psi) |

| PLC Panasonic |

| 110–240V / 50–60Hz |

| 63kg |

| - |

| max. 100 x 200mm |

| 0.5/10mm |

| 1x56,1x70,1x86 mm |

| 1 |

| Module 110 |

|  | |

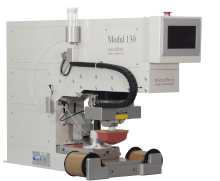

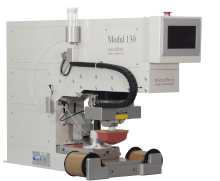

| wo.c. 1800/hr, w.c. 1200/hr |

| max. 750N |

| pneumatic & linear motor |

| 78 l/min |

| 5–6 bar (87 psi) |

| PLC Beckhoff |

| 110–240V / 50–60Hz |

| 92kg |

| - |

| max. 130 x 250mm |

| 0.5/10mm |

| 1x56,1x70,1x86,1x120 mm |

| 1 |

| Module 130 |

|  | |

| wo. c. 1600/hr, w. c. 1100/hr |

| max. 1750N |

| pneumatic & linear motor |

| 245l/min |

| 5–6 bar (87 psi) |

| PLC Beckhoff |

| 110–240V / 50–60Hz |

| 159kg |

| - |

| max. 170 x 330mm |

| 0.5/10mm |

| 1x120,1x140,1x160 mm |

| 1 |

|

|  | |

| o. R. 1500/h, m.R.1000/h |

| max. 3000N |

| pneumatic & linear motor |

| 270 l/min |

| 5–6 bar (87 psi) |

| PLC Beckhoff |

| 110–240V / 50–60Hz |

| 180kg |

| - |

| max. 220 x 420mm |

| 0.5/10mm |

| 1x140,1x160,1x180,1x200 mm |

| 1 |

|

|  | |

Catalog

Catalog  Book

Book